Bearing Calculation and Analysis Capabilities – AxSTREAM®

Related Articles

AxSTREAM® Software Platform

The AxSTREAM® software platform for multidisciplinary design, analysis and optimization provides an integrated and streamlined approach to turbomachinery design. This best-in-class software solution encompasses the complete process for radial, axial ...

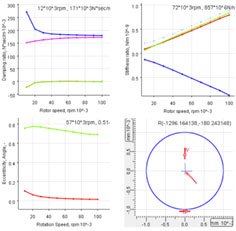

Rotor Dynamics Analysis Capabilities – AxSTREAM® Introduction

Without proper rotor dynamics analysis, rotating machinery is at a higher risk of failure during operation. It is with this in mind that rotor dynamics software is arguably one of the most important tools in the turbomachinery design process. The ...

Axial Turbine Design Software – AxSTREAM® Platform Overview

The AxSTREAM® platform for multidisciplinary turbomachinery design, analysis and optimization software tools provides a fully integrated and streamlined solution for the complete flow path design process of axial turbines. Starting from the ...